Selected:

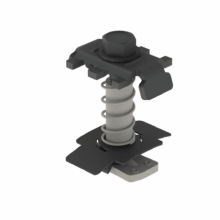

IronRidge® Ground Mount System

Join Our Newsletter

Receive exclusive offers, invitations, and updates when you sign up for our newsletter

- info@practicalpreppers.com

- (864) 915-1855

-

110 Johnson Street

Suite 1287

Pickens, SC 29671

© 2025 Practical Preppers. All rights reserved. A PressGo Digital website